Photoplast

Simple, Sustainable, Safe

An energy storage solution inspired by nature

Our Vision

Reduce the waste of valuable materials

Repurpose Electric Vehicle Batteries

Promote renewable energy sources

Help preserve our environment

The PhotoPod

Simple, Sustainable, Safe

The Photopod is a ‘micro' power-converter that will convert low voltage direct current (DC) from a solar panel to high voltage DC to charge an electric vehicle battery.

Our product will include maximum power point tracking to improve efficiency and utilize a flyback converter to reach the required output voltage.

The micro converter is built in a waterproof, corrosion-resistant housing intended for use in residential, recreational, and marine environments.

LCD Display

This Display shows the input voltage and current from the solar panel, internal temperature for overheat safety, and output voltage seen by the battery.

Micro-Controller

The Arduino Uno is a perfect choice for our controller, offering several digital I/O, PWM output, and the 4 required analog inputs.

Interactive PCB

Hover Over the Circles!

Linear Power Regulator

Our design incorporates 5V and 12V regulators to supply power to the controller, op-amps, driver circuits,

and the display.

MOSFET Driver Controller

The driver was added to the circuit to precisely switch the MOSFET on and off 111,000 times per second!

Shunt Resistor + Instrumentation Amplifier

The instrumentation amplifier accurately measures the voltage across the precision shunt resistor (40 mOhm) and feeds the value to the controller, where it is converted to a current measurement.

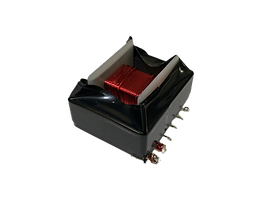

Flyback Transformer

The DC/DC converter operates with three custom flyback transformers boosting the input voltage 20+ times to the required output to charge the EV battery.

Power Mosfet

The MOSFET opens and closes at 111kHz, allowing the DC input to be stepped up by the flyback transformer.

Voltage Divider

We've used a simple voltage divider with low tolerance resistors to get the most accurate voltage reading.

Snubber Circuit

The snubber is used to suppress transients and voltage spikes that can damage sensitive circuitry.

Output Signal

The transformer's output is rectified with a fast-switching diode and sends current at 400 volts to the EV battery.

Communication Signals

The PhotoPod sends signals to ensure the battery is ready to be charged and only sends power when the sun is out!

Voltage Reference

To maximize the accuracy of voltage, current, and temperature measurements, we're suppling a precise reference voltage to the controller externally.

Temperature Sensor

A thermistor is placed near the MOSFET, picking up temperature rises as quickly as possible to prevent overheating.

Input Signal

Solar power enters the PhotoPod through the input connector and 8A fuse for added safety.

Figure 1 - PhotoPod PCB, Revision 2

A custom design, handmade with precision

The Flyback transformers used in the PhotoPod's converter are built specifically for our solar storage application, and have been operated with an output exceeding 800 volts.

Rugged Waterproof

Non-corrosive

The Photopod is designed to handle any environmental conditions.

With an IP67 enclosure and watertight connectors, the device will keep you energized through the roughest weather.

A solution for the future

Figure 3 - Waterproof Enclosure Video

Sustainable energy storage solutions are a huge hurdle faced by humanity.

However, nature has allowed for a simple solution:

Storing solar energy as chemical energy, like chloroplast performing photosynthesis.

This is already the primary source of energy for our planet!

Figure 4 - population of PCB

Project Timeline

Figure 2 - Transformer Winding Video

Gallery

The Photoplast Team

Daniel Pedro

Daniel has a passion for sustainable energy generation and electronic design. Throughout the project term, Daniel assisted the team with coding, hardware testing, documentation. After completing the Advanced Electronics Diploma, Daniel will complete the Engineering Bridge program before transferring to UVIC to obtain a Bachelors Degree in Electrical Engineering.

Email: Danielp198@hotmail.com

Nic Lockwood

Nic enjoys repairing broken electronics and computers in his spare time. Nic mainly focused on software and documentation this project term. After completing the Electronics Diploma, Nic will transfer to UVIC to finish his Bachelors Degree in Electrical Engineering.

Email: nwl721@gmail.com

Navin Francis

Throughout the project term, Navin worked with the hardware and transformer design. He also assisted Daniel with the maximum power point tracker code. Navin has worked in the marine sector in India before moving to Canada to pursue further education. To accelerate a career in marine industry, he's completing the Electrical - Marine & Industrial program.

Email: navineee7@gmail.com

Philip Shuck

Philip completed initial design calculations and worked on component sources. Following the troubleshooting stage of the project, he learned PCB design in Altium and built two revisions of the PhotoPod board. After completing the Electronics Diploma, Philip will transfer to UVIC to obtain his Electrical Engineering Bachelors Degree.

Email: pdshuck@gmail.com

Sponsors

The Photoplast Group would like to thank Lindsay Stretch for sponsoring the development of this product. Lindsay's continued involvement in the project gave us a outside perspective that enabled us to optimize our design for the end user and ensure safety, simplicity, and sustainability.

Additionally, we would like to thank the Camosun instructors and electronics prep-room staff for helping us source the most suitable components and for offering technical insight and solutions.

Contact Us

Do you have any questions or inquiries about our project? Feel free to contact us using the email provided or messaging section below.

Camosun - Interurban Campus Address:

4461 Interurban Rd, Victoria, BC V9E 2C1

Email:

Figure 16 - The Photoplast Group

Please join us at the 2021 annual Camosun Capstone Symposium. The event is held in the CTEI building at the Interurban Campus from 10:00 am-2:00 pm on December 15th, 2021.